| |

The Life Rail System

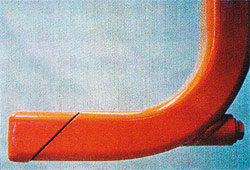

The Stanchion Offset

The offset is the mid-section of the Life-Rail stanchion which consists of 2 bends.

The purpose of the stanchion offset is to meet W.C.B requirements with regards to using wire rope as a guard rail (i.e., 12" in from the outside edge).

This offset allows comfort in safety while walking the panels.

In consideration of other trades, the offset is in place to assist in safe completion of their obligations (i.e. roofing, membrane and flashing can sasfely be installed with no interference).

The Pass-Through Coil

The Pass-Through Coil is designed for simplicity.

There are two coils on each stanchion, one is located at the top (1), and the other is approximately 21" lower (2), which assists in establishing guard rail status.

Trades people are able to stay clipped to either cable while passing through a stanchion.

The design facilitates easy installation of the horizontal life line by enabling you to engage the 3/8" wire rope without pulling through lengthy cables.

When dismantling, the pass-through coil also allows easy removal of intermediate stanchions while maintaining W.C.B requirements with regards to fall protection.

The Horizontal Life Line

The horizontal life line consists of 300 ft., 3/8" engineered certified wire rope.

The horizontal life line is divided into 300 ft. sections, each section of the life line is to be no longer than 300 ft. in order to meet engineer requirements.

The Anchor

The Life Rail anchor is located at the bottom of the rail stanchion and consists of an anchor wedge and bolt. Simply establish full penetration with a guard rail into a Life Rail panel insert, then tighten the anchor bolt to a minimum of 75 foot pounds (a strong pull on a wrench).

An additional advantage to the Life Rail anchor is on completion of the project, the rail stanchion can be released simply by a secure worker loosening the anchor bolt and removing the rail, thus eliminating the need for expensive equipment.

The Panel Insert

The Life Rail panel insert is constructed of light-weight, durable PVC plastic in order to prevent any future corrosion. It is also designed to fit all tilt panels (ie. wall thickness).

A paint grade, flush mounted cap is supplied with the insert. The purpose of this cap is to withhold concrete from entering the insert during the pour. It simply snaps in place to cover the cavity on completion of construction.

The stability legs of the panel insert facilitate hassle-free installation by simply replacing the rebar chair or chairs in the desired location with the unit.

The insert is sealed off and does not protrude to the inside face which prevents possible leakage and minimizes concrete finish.

|

|

About Life Rail Ltd.

Until recently, fall protection for the trades required to complete roofs of their tilt-up projects was a complicated business.

Control zones have been used, but the zone delineator posts had to be moved frequently and the crew members acting as monitors don't get any work done. Tie-off zones have also been used but have to be changed frequently as the work processed, which is very inefficient.

Now fall protection for many companies is a snap. A single perimeter system provides both fall protection and arrestment for all the aerial trades from the ironworkers to the roofers.

A new system designed specifically for tilt-up construction was designed by John Letourneau of British Columbia called the Life Rail. This product uses gooseneck stanchions fastened to inserts cast into the tilt-up panels.

Steel cables stretched taut, and strung through upper and lower pass-through coils on the stanchions functions both as guard railing and as life lines to attach safety harness lanyards. The system is installed as soon as the tilt-up panels have been raised and braced. It remains up until after the roofing, including parapet flashing, is completed.

The gooseneck shape of the posts offsets the cable barrier inward at the top of the panels so ironworkers can walk and stand on the top edge of the panels secured by their safety lanyards to the cable lifelines. Because the top edges of the tilt-up panels are not obstructed, deck and roofing installation is not hindered later on.

When crews must work outside of the Life-Rail perimeter, on building corners designed without tilt-up panels for example, workers clip their lanyards to the nearest Life-Rail cables for fall protection. Additional cables can also be strung across the top of the tilt-up structure as lifelines for ironworkers erecting beams and steel joists or other trades working near roof openings.

While the Workers' Compensation Board of B.C. does not approve or endorse any safety product, when used properly the Life-Rail system complies with worksafe B.C's Guidelines.

The Process

Use of the Life-Rail system begins with the placement of the PVC inserts in the tilt-up panel forms. Only one insert is required for each stanchion.

Once the panels are erected, the 16-kilogram steel stanchions are mounted in the inserts. Tightening a single hex bolt in the anchor prong secures the stanchion. The posts stand 38 mm out from the panel surface, permitting painting and installation of parapet caps.

Clever pass-through coils on the stanchions provide extra versatility. Not only can stanchions be added or removed without unstringing the line, but also lanyard clips can slide along the cables past the stanchions without unhooking.

Single lengths of up to 90 meters of cable can be strung along the stanchions, which can be spaced up to 8 meters apart. Tensioning only requires a come-along with a cable gripper (which is supplied).

Depending on the position of the anchor inserts and the thickness of the roof assembly, the cable heights vary from 500 to 800 millimetres (lower cable) and 1050 to 1350 millimetres (upper cable).

When high work is completed, the Life-Rail system can be dismantled from the rooftop. Plastic, paintable flush-mounted caps close the insert openings.

"With Life-Rail there's a railing around the roof protecting every trade up there. No more control zones, monitors, or guys having to crawl on hands and knees when they're near the edge," says Letourneau. "The Life-Rail system is simply designed to save lives."

|

|